Chevron Australia

Amy James

6.30 AM

Time to wake up and get ready for the day! I take a shower, have my breakfast, and then catch the train into the city.

7.45 AM

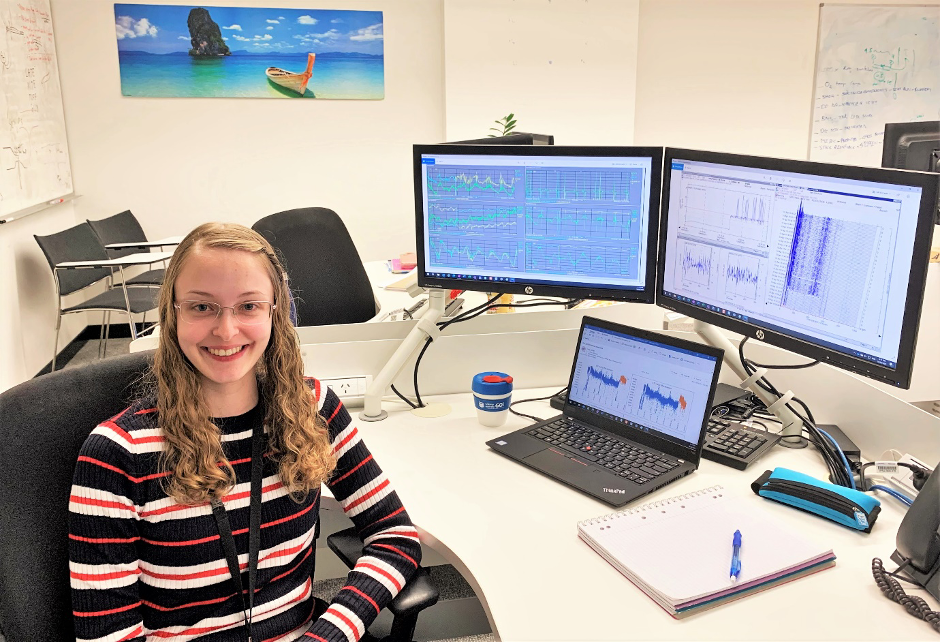

I arrive at the office and make my way to the Integrated Operations Centre, which is reserved for the teams who provide day-to-day support to our LNG operations. I am currently working as a Systems Engineer in the Wheatstone Utilities Team, specialising in Rotating Equipment.

The first thing I do when I get to work is make myself a cup of tea. I then spend a few minutes chatting to my team before sitting down to read the Wheatstone Morning Operations Report. This report provides a summary of everything that has happened in the plant over the last 24 hours. As a Systems Engineer, it is important for me to keep up to date with everything happening in my systems of responsibility, so I can provide support where needed.

8.00 AM

After reading the morning report, I dial into the daily operations call with site. This is a quick meeting between the engineering teams in Perth and key stakeholders on site, such as Production, Maintenance, and Frontline Engineering. During the meeting we align on our priorities for the next 24 hours and discuss any roadblocks or emerging issues. If there are any issues in my systems, I will be called on to provide support, but there’s no emergent work for me today. Everything is running smoothly!

8.30 AM

I start going through my emails, responding to the ones that need a quick reply and flagging the ones that need more detailed responses. I’ll get back to these later in the day. I then start my daily “equipment health checks”. An important part of my role is to monitor the condition of key pieces of rotating equipment within the Utilities area of the plant. We receive continuous data on this equipment from various sensors which track things like pressure, temperature, vibration, etc. By monitoring these properties we can detect changes in equipment behaviour and identify early signs of failure. This allows us to schedule maintenance at the right time, avoiding unplanned outages and minimising lost production.

As part of my daily checks I go through the event log in our software to check if any of the sensors’ alarms have activated. Some of the alarms I can dismiss quite easily (e.g. a piece of equipment turning on), but others will require further investigation. I make a note of these anomalies to check after my next meeting.

9.30 AM

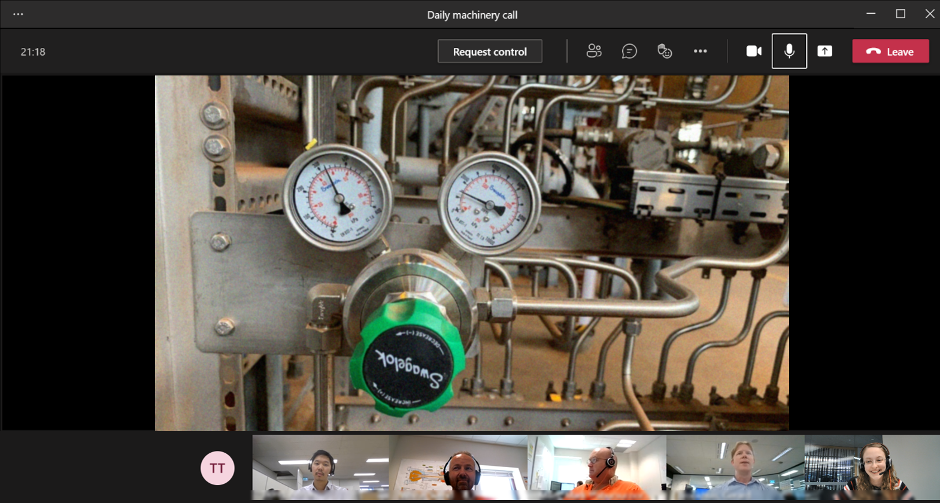

It’s time for my favourite meeting of the day – the daily machinery call! This is a meeting between all the Rotating Equipment Engineers supporting the Wheatstone plant, both in Perth and on site. During this meeting we discuss any equipment issues or improvement opportunities, and brainstorm solutions together. I love this meeting because everyone is so passionate about what they do, and I always learn something new each day!

We also use this meeting to do “live” troubleshooting in the plant. Today one of the Perth engineers found that we needed to increase the seal gas pressure on one of our compressors, which can only be done by adjusting a valve out in the field. The frontline engineer went out with a technician and dialled into the call from the plant itself. We were then able to watch “live” as they adjusted the valve, and by monitoring the trends from Perth we could provide instant feedback on where to position the valve. Teamwork at its finest!

10.00 AM

I now have time to do a thorough review of the equipment anomalies I found earlier in the day. The first thing I do is look at the vibration trends, as this usually provides the most information about what’s going on in a machine. I then check the process variables such as pressure and temperature to see how these have changed over time. Finally, I use some machine-learning software to see how the current behaviour of the machine compares to its “predicted” behaviour. Looking at all these trends lets me see a clear picture of the machine’s “symptoms”, which I can then use to work backwards to come up with a “diagnosis”, and finally a recommended solution. It’s like being a doctor for machinery! Once I’ve settled on the most likely cause of the problem, I raise a work order for the maintenance team to investigate and resolve the issue.

11.00 AM

I respond to a few more emails and then get stuck into some bigger tasks. I have two major projects I am working on at the moment – one is a system upgrade project, and the other is an emissions reduction project. These are very exciting projects to be involved in, but they are both medium-term projects which will go on for several months. In the short term, I am also working on a few small projects focused on improving the reliability and operability of my systems. These small projects typically involve a few small changes to the plant, such as upgrading the material of a pump shaft or increasing the size of a valve. As a Systems Engineer I get to work on a lot of multi-disciplinary issues, which is great for broadening my knowledge beyond my base discipline.

12.00 PM

It’s lunch time! I usually bring my own lunch from home but there are plenty of great places to eat nearby. The local Japanese is particularly popular (and is certainly a favourite of mine!). Today I ate lunch with some other graduates in the courtyard next door to our building – there are always a few of us hanging out there.

1.00 PM

It’s risk assessment time! Today I took part in a Hazard and Operability study (HAZOP for short). The purpose of a HAZOP is to identify and evaluate all the potential risks associated with each system in the plant. Preventative and mitigative safeguards are then put in place to reduce the likelihood and consequence of each hazard scenario. HAZOPs were completed for each system in the design phase, but we need to re-validate these risk assessments every few years to confirm that every hazard scenario is covered and sufficient safeguards are in place.

Today we looked at the Condensate Storage and Loading System. The HAZOP team (consisting of systems engineers, process engineers, and key operations personnel on site) systematically go through each section of the system, identifying risks and safeguards by talking to the people who operate the system, as well as looking at process flow diagrams, piping & instrumentation diagrams, control narratives, etc. Performing a HAZOP is a very involved process – analysing one system from beginning to end usually takes a few weeks! I’m just sitting in for a few hours today to watch and learn.

3.00 PM

All my meetings are now done for today and I’m determined to smash out some work this afternoon, so I make my way over to a “huddle room”. These are quiet rooms separated from the rest of the office and are great places for getting work done without being disturbed. I put on my headphones to listen to some background music and then get cracking – I want to finish writing up a procedure and get started on some pump performance calculations before tomorrow.

4.45 PM

It’s now time to start wrapping things up for the day. I finish responding to emails, make a quick to-do list for tomorrow, and check my calendar to confirm what meetings I have on tomorrow. Then that’s another day done!

5.00 PM

I usually head home straight away, but every now and then there will be some sort of social event after work, whether it’s casual drinks/dinner with my team or a formally-organised event planned by the social club or graduate committee. Tonight I had dinner and drinks with my old team (where I completed my first rotational assignment at Chevron). Even though I’ve moved roles into my second rotation, I still catch up with my old team quite regularly – we have a really great relationship and still keep in touch via our group chat!

8.30 PM

After a great night out with my colleagues, it’s time for me to head home and get ready for another exciting day tomorrow!